Quality

Quality is Designed into our process.

Our inspection lab is simply there to prove it!

Solid Machine’s goal is to engineer total process control, we believe that quality engineering yields quality components. It’s just that simple!

ISO Certified

With improved service to our diverse customers in mind, Solid Machine developed and implemented a quality system certified to ISO 9001:2015 in 2017. A key aspect of our quality system is our ability to retain material traceability for any product throughout the "manufacturing" process, as well as imposing controls over any outside secondary processes. Statistical tools are utilized as appropriate both during the manufacturing and inspection processes to ensure that we conform to predicted results.

FFL License & ITAR Registered

Solid Machine received our Federal Firearms License (FFL) from the ATF which permits us to manufacture serialized firearms components.

We are also ITAR registered with the Directorate of Defense Trade Controls (DDTC) per the Arms Export Control Act (AECA).

Solid Machine can supply Defense Federal Acquisition Regulation Supplement (DFARS) compliant components as required.

Lean Manufacturer

Solid Machine practices the principles of lean manufacturing. Lean is centered on preserving value with less work. Lean is a production practice that considers the expenditure of resources for any goal other than the creation of value for the end customer to be wasteful, and thus a target for elimination.

One of Solid Machine’s lean innovations is a paperless production flow, job traveler, and inspection report system that is utilized to manufacture over 10,000 parts per week. Our well-trained operators use a custom online database to find and complete documents creating tremendous efficiencies and can notify our clients when a job is done to create and send packing lists at the click of a button from their work stations. Paperless manufacturing and inspection does more than save paper and the environment. It speeds up decision making, empowers our employees, and is a productivity boost for the entire company.

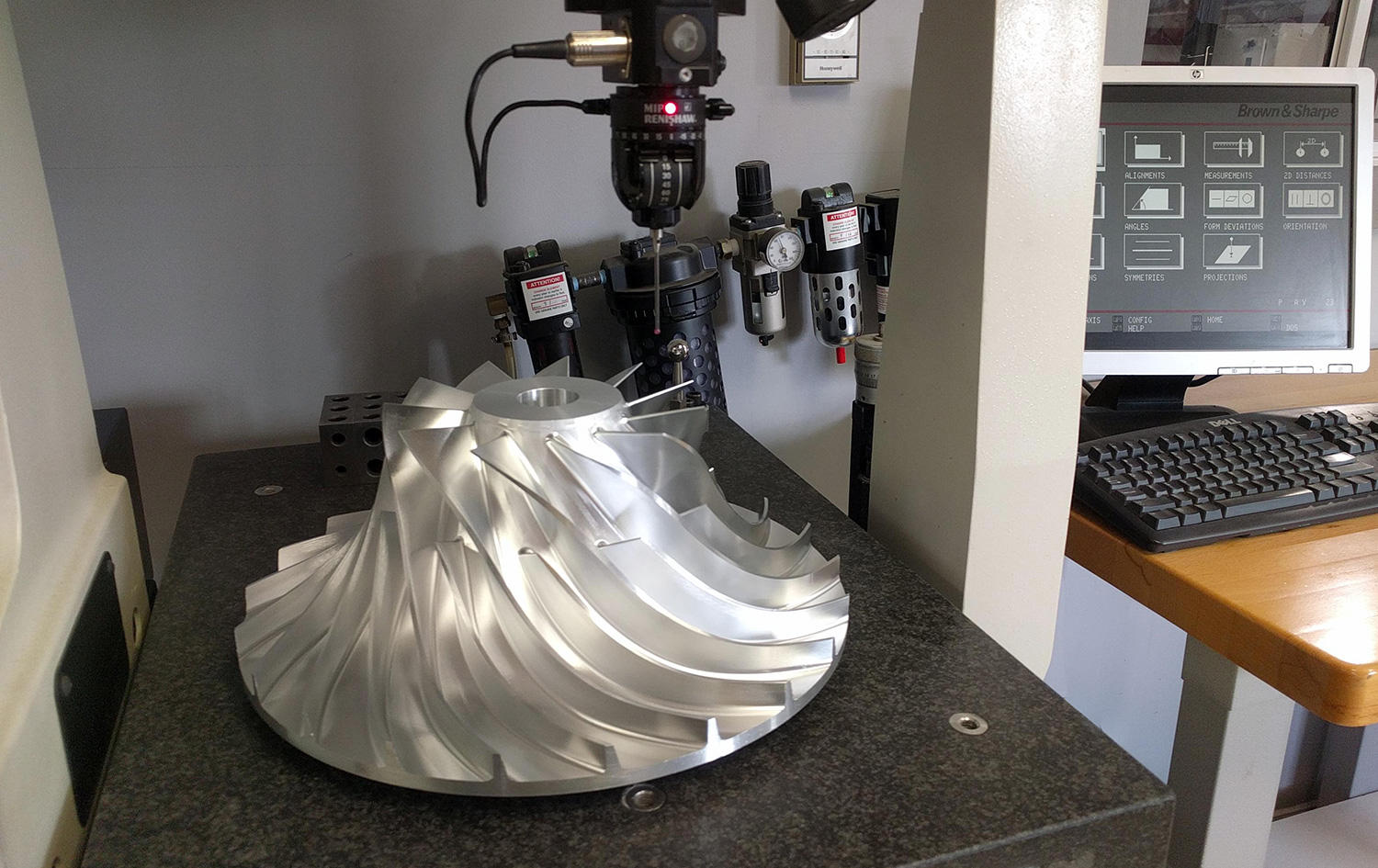

Metrology

In order to ensure concise measurements, Solid Machine leverages a B&S Micro-Val CMM with a 24” x 18” working envelope. We maintain a gage calibration system per ISO10012-1 and have 300 inspection instruments in our database. We are a "Dock to Stock" or "Certified" supplier to many of our customers because of these systems and controls.

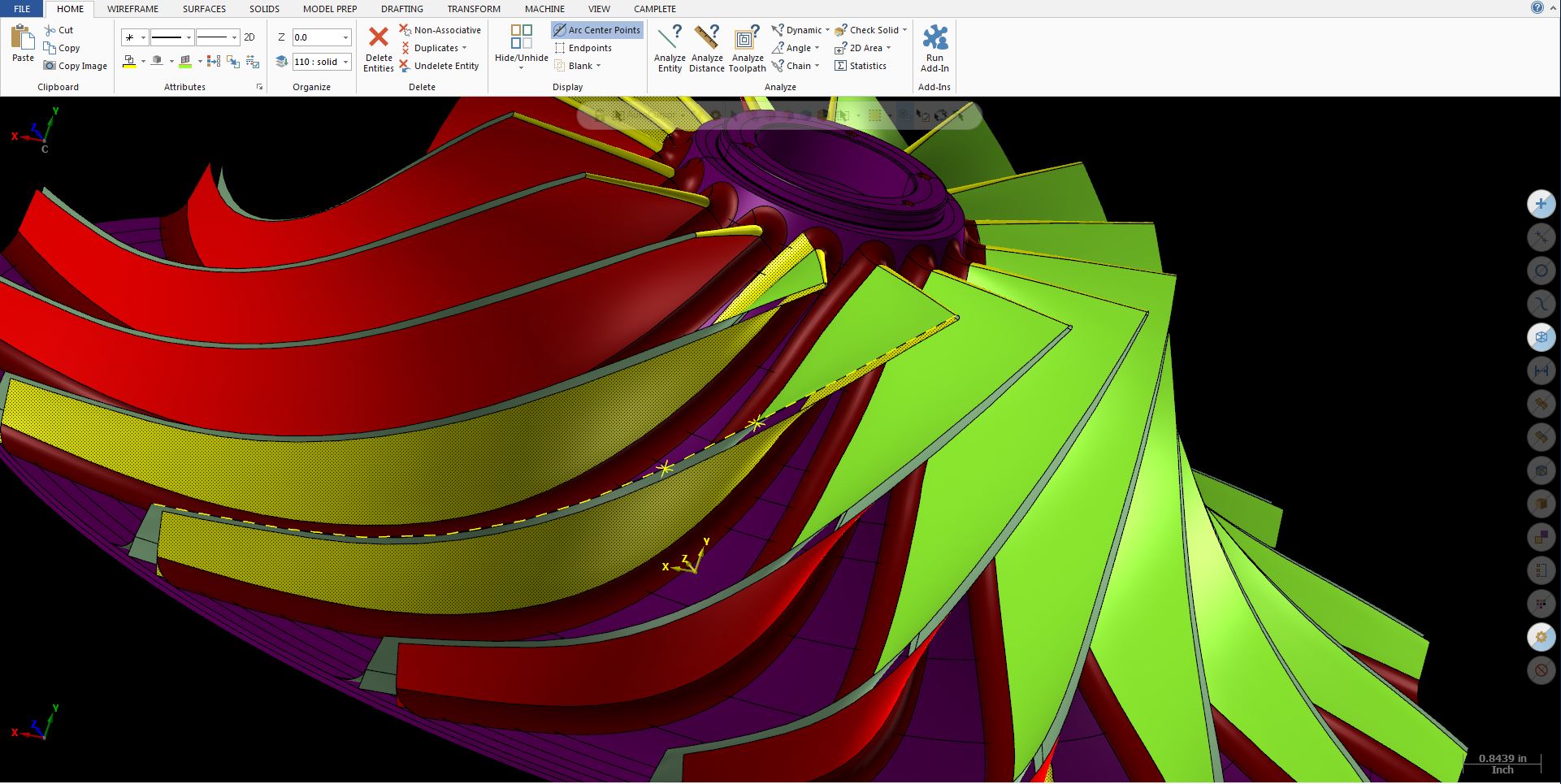

Reverse Engineering &

Part Digitalization

Solid Machine is capable of building a 3-D model from our inspected geometry. Once a model has been built, the component can be manufactured. This is a tremendous benefit for customers trying to replace damaged hardware or who need older parts with no 3-D model available. Solid Machine has a proven track record in this area for providing dependable results and fast turnaround.

Quality Manual

Our Quality Manual is intended as a guide to the major aspects of the Quality Control and Assurance systems employed at Solid Machine.

Clients are invited to review the latest copy of our Quality Manual.

“From prototyping to production, we stand behind everything we make to be on-time and on-spec. Guaranteed.”

— Brian Godbout, President & Owner of Solid Machine

Solid Machine | 61 Airport Dr.- Unit 1 | Rochester, New Hampshire 03867

Phone: (603) 332-5511 | E-mail: info@solidmachinenh.com