SUMMARY

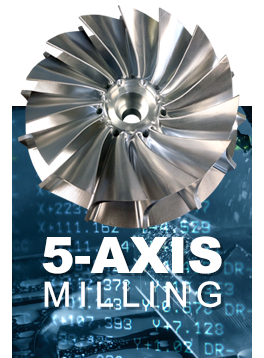

If you need advanced 5-axis machining services, you have come to the right place.

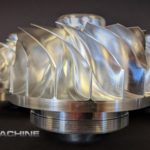

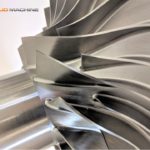

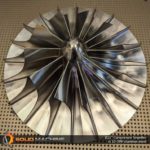

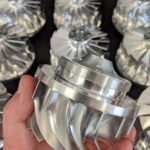

Solid Machine performs high-speed, simultaneous 5-axis milling on up to 3,000 parts per month by both flank and point milling including turbocharger impellers, aero-engine spacers, compressor impellers, turbines, pumps, blades/vanes, and custom hardware up to Ø26.0” (660mm).

Our talented team has decades of experience in the machining of rotating bladed turbomachinery hardware in a wide range of materials to the tightest dimensions and most stringent specifications. We are more than a “chip cutter” and can suggest more efficient manufacturing methods, processes, and design changes that will meet your needs, while lowering your production costs.

Whether you need a complex prototype or high-volume production, contact us to experience the difference Solid Machine can make in bringing your product or vision to life.

SHOWCASE

We hope the following gallery provides a glimpse at the diversity, quality and workmanship of our manufacturing solutions.

SOLUTIONS & SPECIFICATIONS

|

Max Diameter: |

26.0” (660mm) |

|

Max Height/Length: |

24.6” (625mm) |

|

Max Weight: |

4,400 lbs (2000 kg) |

|

Materials: |

|

|

Tolerances: |

+/- 0.0001” to 0.0002” depending on the feature, alloy, etc. |

|

Internal Capabilities: |

|

|

Subcontracted Services: |

|

|

Lead Time: |

Quoted on a job by job basis, but typically under 6 to 8 weeks ARO. |

|

Software: |

|

|

File Formats: |

We have yet to receive a model or drawing file we could not open. Try us…we’ve got you covered. |

Solid Machine | 61 Airport Dr.- Unit 1 | Rochester, New Hampshire 03867

Phone: (603) 332-5511 | E-mail: [email protected]